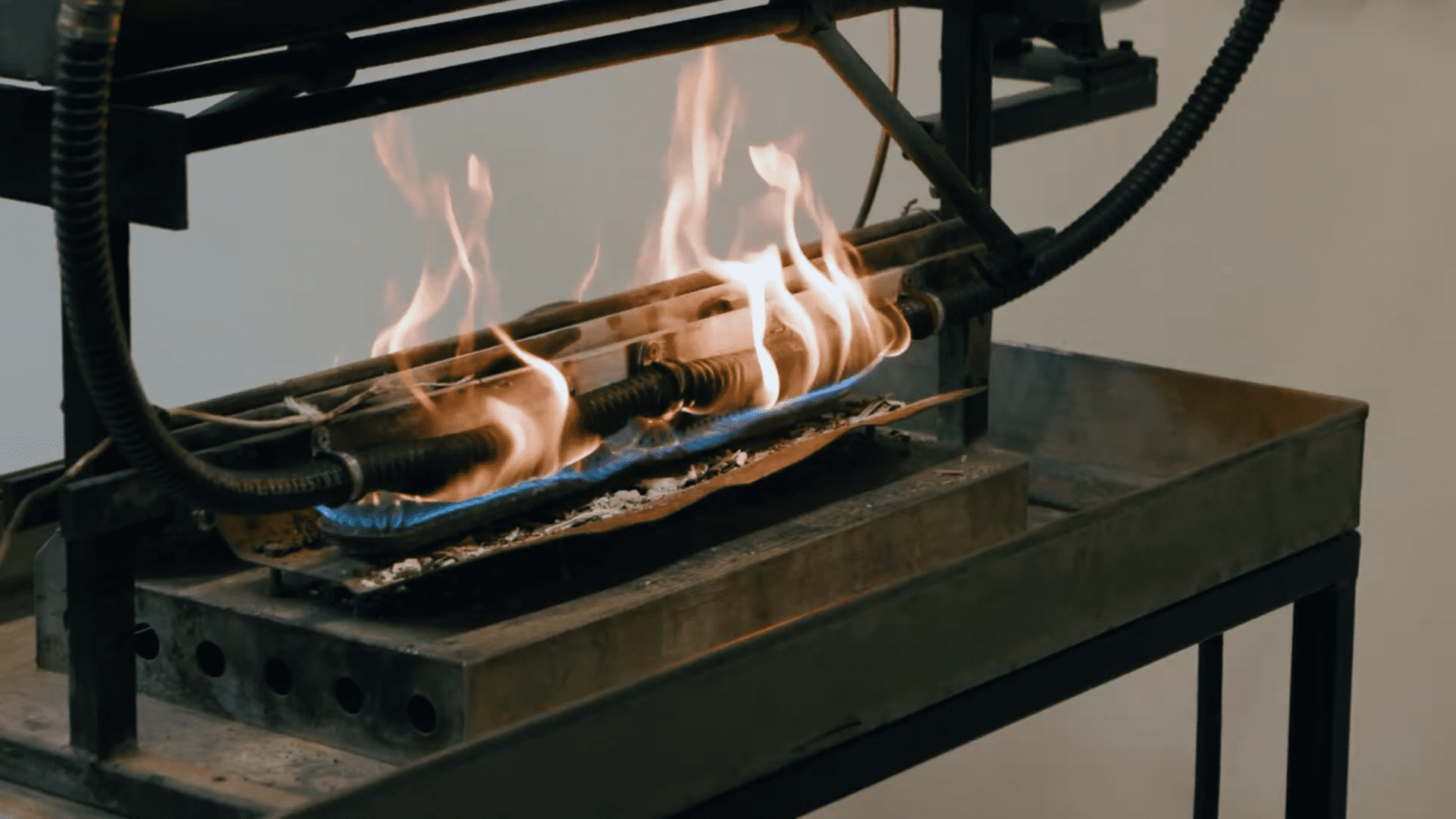

Guelph Twines understands that every component plays a vital role in cable manufacturing, especially regarding fire safety and compliance. That is why our polymer flame-retardant cable fillers have an ASTM D2863 Limiting Oxygen Index (LOI) that exceeds 27%. This means that our polymer cable fillers meet performance benchmarks established using ASTM D2863 testing, which provides a solid foundation for safety and performance.

ASTM D2863 Explained

ASTM D2863 is recognized as the standard for determining the LOI, or the minimum amount of oxygen required to sustain combustion in a polymer. The following ranges are commonly used as guidelines when interpreting LOI results in polymer materials:

- LOI level of less than 21% means the material is easily flammable in the air.

- LOI level at 21% means the material burns readily in the air.

- LOI level in the range of 22% to 27% means the material is moderately flame-retardant.

- LOI level above 27% means the material is flame-retardant.

- LOI level above 30% means the material is often considered self-extinguishing in normal air.

The industry baseline for flame-retardant materials is commonly accepted at 25% LOI.

Guelph Twines Exceeds the LOI Industry Benchmark

In recent third-party certified ASTM D2863 testing, Guelph Twines’ polymer flame-retardant cable fillers achieved an LOI of above 27% — exceeding the commonly accepted 25% benchmark for flame-resistant materials. This result highlights our continued investment in polymer formulation and quality control, delivering safer, more reliable filler solutions for cable manufacturers.

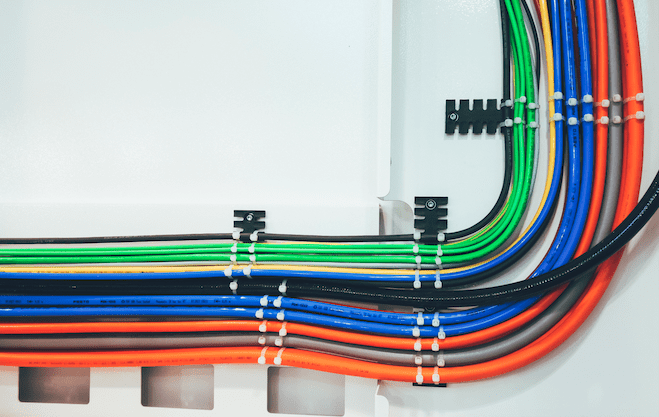

What This Means for Cable Manufacturers

- Third-Party Verified LOI Results: ASTM D2863 compliance is a common line-item requirement in RFQs. With Guelph Twines, you now have third-party validation and test results on file, simplifying vendor approval and audit processes.

- Reliable North American Supply Chain: Our fillers are manufactured locally, reducing lead times and eliminating overseas sourcing risks.

- Cost-Efficient Performance: Fire resistance means fewer quality concerns, less rework, and peace of mind for downstream customers while maintaining competitive pricing.

- Elevated Flame Resistance: A LOI of 27.3% helps reduce flame spread and ignition risks, especially in confined installations or where heat buildup is a concern.

- Formulation Flexibility: Our fillers maintain low shrinkage, easy handling, and compatibility with twisted and untwisted cable configurations.

- Consistency You Can Trust: Tight production tolerances and strict QC protocols ensure every shipment meets specs.

Guelph Twines is Your Partner in Cable Manufacturing

Guelph Twines is committed to engineering excellence, regulatory compliance, and customer-focused support. Whether you’re developing new cable designs or sourcing materials for high-volume production, our ASTM D2863-compliant fillers provide a solid foundation for safety and performance.

Contact Us to set up a meeting or request samples today!

Phone: (519) 821-9140

Toll-Free: 1-888-771-9140

Email: info@guelphtwines.com

Website: www.guelphtwines.com